Iron Ore production in the Pilbara Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto

More

Context 1 ... activities involved in mining and processing iron ore on site are shown in the flow chart in Figure 1. Ore processing ranges from simple crushing and screening methods to...

More

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

More

With the further mining of the reserves, the iron ore contents of the mines are also shrinking. This has already been shown clearly in China and the USA, where the average

More

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing. The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the

More

operation flow of whole factory – iron ore crusher, gold ore . You from operation flow of whole . Level Sensor Selection Theory of Operation ,successful operation of a power

More

2015年8月26日 This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process. Starting from either open-pit or underground

More

iron ore crusher unit flow chart. iron ore pelletisation process flow chart . 26 Dec 2013 ... Iron Ore Pellets the Iron Ore Pelletization Plant and Iron Ore Beneficiation

More

2022年8月4日 iron ore mining flowchart – Vuma Design S. Mar 14, 2018 When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to

More

2022年1月1日 Iron ore crushing and screening. Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BF-BOF) route or through the electrical arc furnace (EAF) route. The majority of world crude steel is made from the BF-BOF route.

More

2020年10月5日 Our research, which includes mining companies across countries and product types, suggests that mine-to-market optimization can generate a 10 to 15 percent increase in earnings before interest, taxes,

More

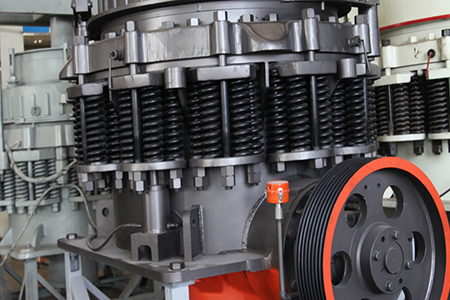

2023年1月1日 In this iron ore deposits (mentioned above), the iron ore was crushed using three stages of crushing to a size below 32 mm and then was subjected to beneficiation. Primary and secondary crushing was done by gyratory crushers. For sticky iron ores with a high clay content, primary and secondary sizers were also used instead of gyratory

More

2021年1月1日 PDF Currently, approximately 1.4 billion tons per year of iron ore tailing ... the weight of the total iron ore mining. 13,18. 1.2 ... During the exploitation of iron ore, crushing rocks ...

More

2015年12月31日 Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study. The environmental impacts ...

More

Ores Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine.

More

2018年6月21日 The flow chart shows the basic steps of how iron ore is used to produce semi-finished products of steel. The individual process steps are explained in more detail in the following articles. Figure: From

More

2016年5月9日 In the flowsheet illustrated the basic steps are shown for the average mill. Primary slimes are treated separately, while the washed and crushed ore is ground, classified, and floated in the usual manner. This

More

2011年1月1日 Iron Ore Conference, Australia, Perth, pp. 20–22. Sengupta M . , 1 9 93 – E n v i r on m en t a l I m p a c t s o f M i ni n g : M o n i t o r in g , R e s to r a t i on , a n d C o nt r o l ...

More

Iron ore is an ore always in demand, due to its use in producing iron and steel bars via Smithing. There are many locations to mine iron ore, but the Mining Guild features several advantages; a trio set of iron ore rocks

More

2022年1月1日 Iron ore crushing and screening. Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BF-BOF) route or through the electrical arc furnace (EAF) route. The majority of world crude steel is made from the BF-BOF route.

More

2023年1月1日 In this iron ore deposits (mentioned above), the iron ore was crushed using three stages of crushing to a size below 32 mm and then was subjected to beneficiation. Primary and secondary crushing was done by gyratory crushers. For sticky iron ores with a high clay content, primary and secondary sizers were also used instead of gyratory

More

2021年1月1日 PDF Currently, approximately 1.4 billion tons per year of iron ore tailing ... the weight of the total iron ore mining. 13,18. 1.2 ... During the exploitation of iron ore, crushing rocks ...

More

2015年12月31日 Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study. The environmental impacts ...

More

2016年3月10日 Crushing Plant Flowsheet Design-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be

More

2009年5月17日 Topic 3: Ore processing and metal recovery From a series of 5 lectures on Metals, minerals, mining and (some of) its problems prepared for London Mining Network by Mark Muller

More

Ores Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine.

More

2015年1月1日 The major iron-bearing mineral in the Muro iron ore deposit is goethite (Fe 2 O 3 .H 2 O) although, hematite (Fe 2 O 3 ) is also an iron-rich mineral found in the ore however, its content is very low.

More

2010年3月1日 Cliffs Natural Resources Pty Ltd (CNR) operates iron ore mines in the Koolyanobbing region of Western Australia, ?50 km north of the town of Southern Cross. Ore is trucked from three...

More

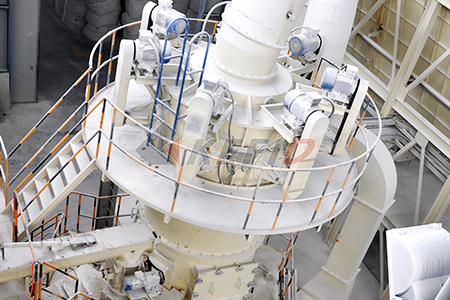

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation,

More